Description

The MP360 four-sided planer / moulder is a high-production, large capacity machine engineered for professional workshops. With a larger capacity and higher hourly production levels than the popular Wood-Mizer MP260 planer / moulder, the MP360 planes and moulds boards on all four sides in a single pass into a variety of professionally finished products.

Features

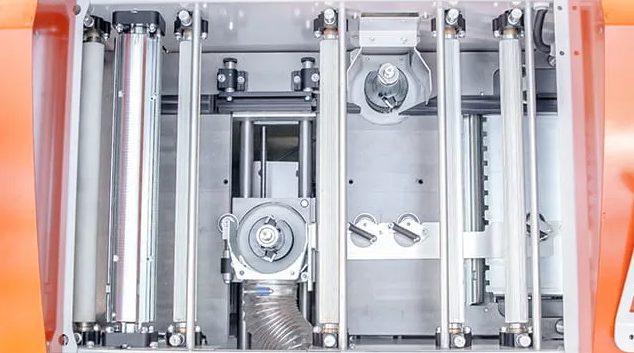

4 Cutting Heads

Four cutting heads plane & mould boards on all 4 sides in a single pass into a variety of finished products.

Five Feed Rollers

Four steel and one polyurethane power roller steadily move the board through the machine.

Large Capacity, Small Footprint

The MP360 features a larger material capacity than the MP260 with up to 20” (510 mm) wide x 9” (230 mm) high one-sided planing/moulding capacity, 16” (410 mm) wide x 9” (230 mm) high 2-sided planing/moulding capacity, and a large 13-3/4” (350 mm) wide x 2” (50 mm) high 4-sided planing/moulding capacity in one compact machine. The MP360 side cutters can be upgraded to 4" (100 mm), 5" (130 mm), or 6" (160 mm) to increase the height capacity for 4-sided processing. The 6" (160 mm) side cutter requires an additional spindle extension.

Large Viewing Window

A large viewing window allows the operator to supervise the entire cutting process from rough sawn boards to final products. Inside the machine, the top and bottom horizontal cutters and two vertical side cutters process the material at 6,000 rpm to ensure a smooth and consistent finish on one, two, three, or all four sides depending on which cutters are activated.

Videos